Accredited Calibration that Meets Every Industry Standard

Calibration regulations vary across industries, but the expectations are the same — accuracy, traceability, and consistency. ICS bridges these requirements with precision calibration programs that integrate seamlessly into your quality system.

All work performed by ICS is carried out under ISO/IEC 17025 accreditation, ensuring that each measurement result is backed by internationally recognized quality assurance. Our laboratories and on-site calibration teams operate with NIST-traceable reference standards, giving your organization confidence that your instruments perform reliably and meet regulatory expectations.

ICS doesn’t stop at accuracy. We focus equally on the documentation and procedural rigor that help your team stay compliant during audits, inspections, and certifications.

Calibration Standards We Support

ICS offers calibration services that align with the world’s most widely recognized standards and regulatory frameworks. Whether you’re manufacturing aerospace components, medical devices, or automotive parts, our procedures ensure your equipment meets both technical and compliance requirements.

For organizations working within ISO/IEC 17025, our accredited laboratories demonstrate full competence in testing and calibration. Aerospace manufacturers can trust ICS to adhere to AS9100, FAA, and NADCAP requirements, ensuring that precision tools, torque devices, and instrumentation perform within strict tolerances.

In the medical sector, our team understands the documentation and process control expectations outlined by ISO 13485 and FDA 21 CFR Part 820, maintaining traceable records vital for patient safety and device reliability. Automotive and industrial clients benefit from our experience with IATF 16949 and ISO 9001, ensuring production consistency, process validation, and equipment reliability across every calibration interval.

Every calibration is accompanied by audit-ready certificates that capture as-found/as-left data, environmental conditions, and NIST traceability, making documentation simple and defensible during internal or third-party audits. preparing for an audit, certification, or internal quality review — ICS ensures your measurement data stands up to scrutiny.

How ICS Keeps You Audit-Ready

Regulatory readiness requires more than accurate instruments — it requires complete documentation and controlled procedures. ICS integrates compliance support into every stage of the calibration process. From initial service planning through final certification, our systems are designed to satisfy traceability, record retention, and documentation requirements under multiple international standards.

Each calibration includes a detailed certificate with traceable measurement data, “as-found” and “as-left” readings, and environmental condition records. These are formatted to align with your internal quality management systems and regulatory body requirements.

ICS also provides preventive maintenance and calibration scheduling services to help clients avoid missed intervals, nonconformities, or audit findings. Whether you’re preparing for an FAA inspection or ISO recertification, our documentation practices are built to make compliance easier, more consistent, and more transparent.

Supporting Quality, Compliance, and Engineering Teams

ICS partners with professionals across quality assurance, production, and procurement roles who rely on accurate and compliant calibration to keep operations running smoothly.

For Quality and Compliance Managers, our audit-ready certificates and process control records remove the uncertainty of inspection preparation. ICS ensures that each calibration meets or exceeds your required standard, reducing the stress and administrative effort associated with compliance documentation.

Procurement and Supply Chain Managers benefit from a single-source calibration partner that understands industry regulations across multiple sectors. We streamline vendor management while ensuring consistent documentation and communication across facilities or divisions.

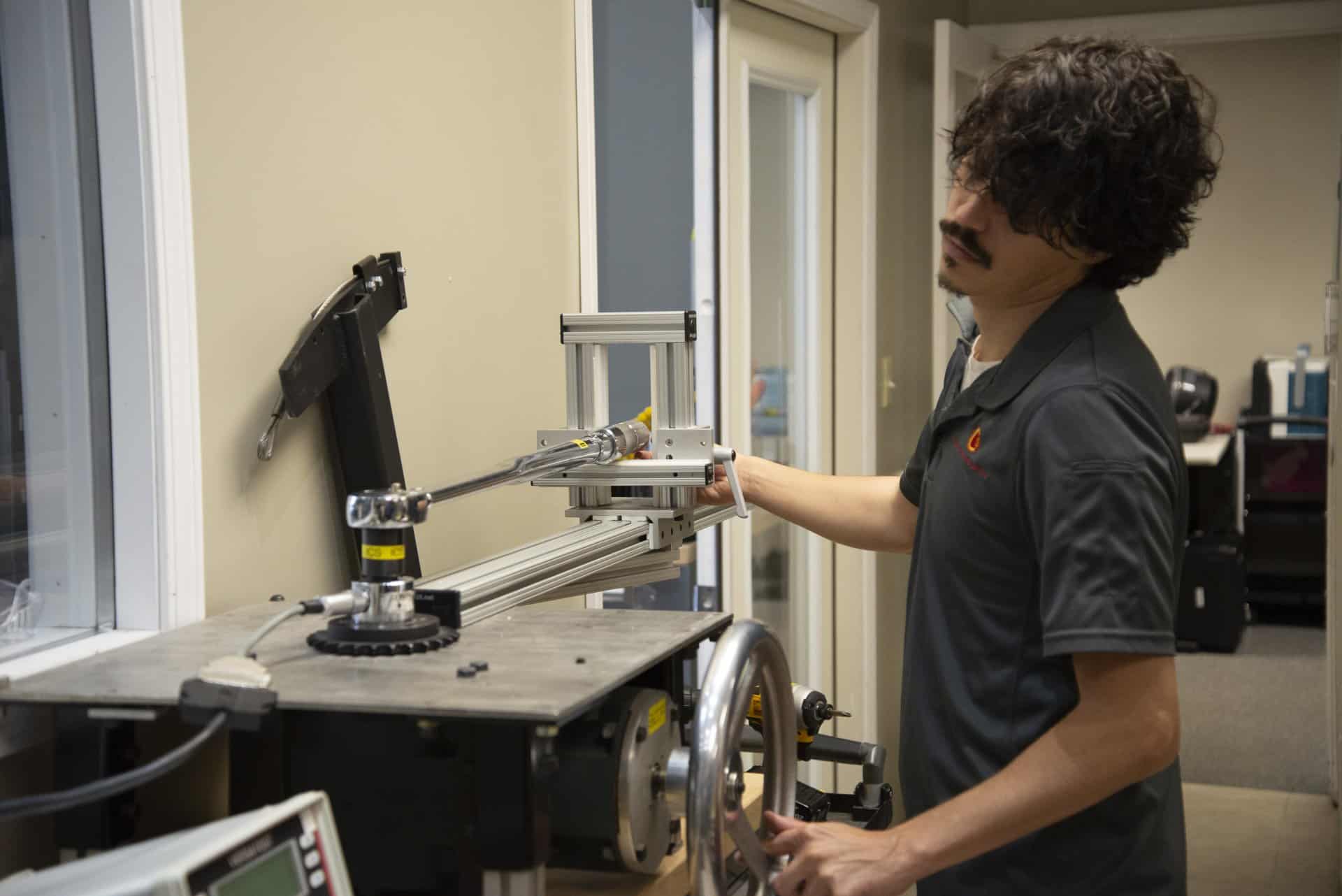

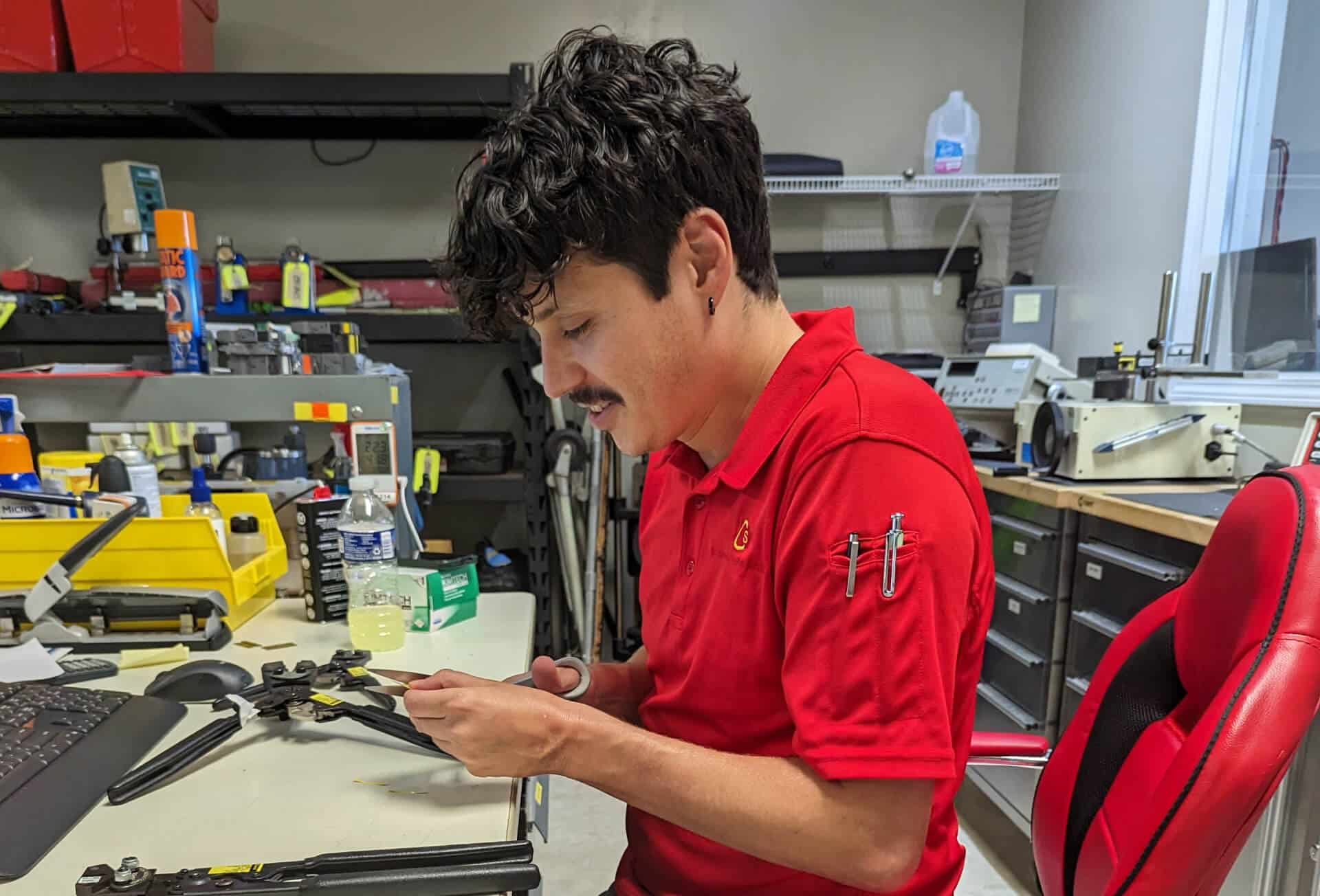

Meanwhile, Engineering and Production Managers appreciate that ICS calibration programs are designed for minimal downtime. Our on-site service capabilities allow production teams to maintain calibration accuracy without interrupting manufacturing or testing schedules.

Stay Compliant. Stay Confident. Partner with ICS.

From aerospace and automotive to medical manufacturing, ICS delivers precision calibration programs built on trust, traceability, and technical excellence. We combine accredited processes with deep industry knowledge to ensure every instrument meets your industry’s most stringent regulatory expectations.

Whether you need documentation that passes an FDA audit or calibration certificates accepted by aerospace OEMs, ICS is your calibration partner for lasting compliance confidence.