Dimensional Calibration Services

Precision Measurement for Peak Performance

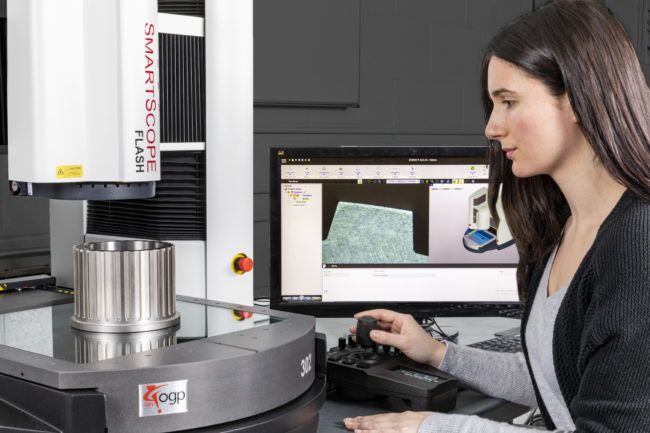

Dimensional calibration is the foundation of reliable measurement in your operations. At ICS, we provide highly accurate dimensional calibration services to ensure your instruments deliver precise and consistent results. Our experienced technicians work meticulously to verify the performance of tools such as micrometers, calipers, and gauges, helping you meet demanding quality standards and maintain trust in every product delivered.

Our dimensional calibration services are tailored to fit your needs, whether in our cutting-edge labs or directly at your facility. Our temperature-controlled, humidity-stable lab environment guarantees that every in-house calibration meets the highest standards of accuracy and consistency, while flexible onsite calibration options are available to minimize downtime. By calibrating your instruments with precision and care, we empower your team to work with confidence, knowing their measurements are right on target.

ICS serves a broad spectrum of industries, from aerospace and automotive to engineering and manufacturing. We’re here to help you maintain compliance, enhance product quality, and eliminate costly errors with precise, reliable calibration. Trust ICS to help keep your instruments — and your business — finely tuned.