Certified Accuracy for Pressure Gauges, Sensors & Instruments

At Instrument Calibration Solutions (ICS), we specialize in precision pressure calibration services for industries where accuracy, safety, and compliance are non-negotiable. Whether you're working with pressure calibrators, digital pressure gauges, or pressure sensors, ICS delivers high-quality, traceable calibration solutions to ensure your instruments meet exact specifications and regulatory standards.

We serve aerospace, manufacturing, energy, defense, and healthcare clients with a full suite of pressure meter calibration and certification services—all backed by ISO 17025 accreditation, NIST-traceable standards, and expert technicians.

What is Pressure Calibration?

Pressure calibration is the process of comparing a pressure-measuring instrument’s output — such as a pressure gauge, sensor, transmitter, or indicator — to a recognized, traceable standard. This process ensures that measurements remain consistent, accurate, and compliant with industry regulations.

Over time, factors like mechanical stress, environmental exposure, and wear and tear can compromise an instrument’s accuracy. ICS uses advanced pressure calibration instruments and techniques to detect and correct these issues, restoring measurement integrity.

For example, calibrated pressure gauges in aerospace must deliver flawless readings to control altitude, fuel pressure, and hydraulics—where precision is vital for flight safety.

Why Choose ICS for Pressure Gauge Calibration?

At ICS, our pressure calibration services are driven by a commitment to:

Measurement Accuracy – Delivering reliable data you can trust

Regulatory Compliance – Fully traceable to NIST and aligned with ISO 17025 & AS9100 standards

Operational Performance – Enhancing instrument reliability and extending equipment life

Risk Prevention – Minimizing hazards from inaccurate pressure readings

Audit-Ready Records – Each job includes a certified pressure gauge calibration certificate

ICS ensures every calibrated pressure gauge meets or exceeds your application demands—so you can operate with confidence.

Our Pressure Calibration Capabilities

ICS calibrates a wide variety of pressure measurement instruments, including:

- Analog & digital pressure calibrators

- Pressure sensors and transmitters

- Manometers and barometers

- Calibrated tire pressure gauges

- Air pressure gauges

- Pressure gauge calibration equipment

- Custom systems used in performance testing and process control

Whether you're looking to calibrate a pressure gauge, verify your pressure calibration instruments, or need a valid pressure gauge calibration certificate, ICS is your trusted partner.

Hydraulic Pressure Calibration

Our Fluke P3224-PSI Deadweight Tester achieves hydraulic pressure calibration from 10 to 10,000 psi with exceptional accuracy—just 0.008% of reading. This makes it ideal for high-pressure systems requiring precise performance validation.

Pneumatic Pressure Calibration

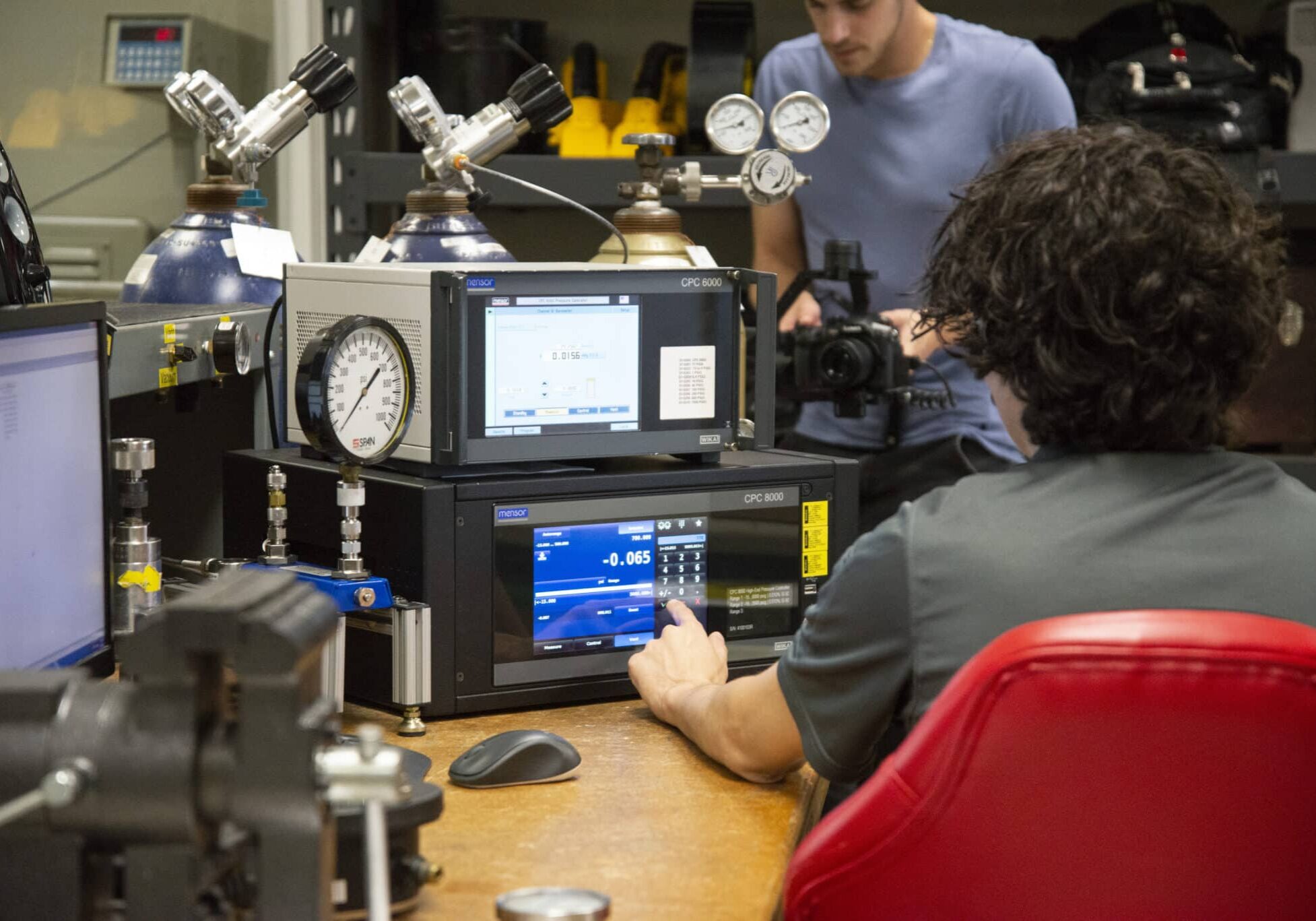

ICS offers multiple pneumatic calibration options to meet your specific needs:

- Mensor CPC6000 Pressure Controller – An automated solution capable of generating vacuum to 1,500 psi with a typical accuracy of 0.01% of reading.

- Pressurements T3500/3 Pneumatic Deadweight Tester – Covers a range from vacuum to 500 psi with 0.01% reading accuracy for mid-range applications.

Comprehensive Gauge Calibration Services

We calibrate and adjust both analog and digital pressure gauges to ensure optimal accuracy and performance. Need a calibrated tire pressure gauge or an oxygen gauge? No problem. Upon request, ICS will:

- Clean oxygen gauges through a certified oxygen cleaning facility

- Seal them in plastic to maintain a contaminant-free state until service reinstallation

With ICS, you can trust your calibrated pressure gauge is ready for action—accurate, certified, and contamination-free.

Industries We Serve

Our clients trust ICS to maintain the precision and performance of their pressure calibration instruments across various critical applications:

- Aerospace & Defense: Calibrating pressure sensors for flight testing, propulsion, and altitude simulation

- Manufacturing & Process Control: Ensuring consistent output with accurate pressure gauge calibration

- Healthcare & Medical Devices: Calibrating sensitive instruments in life-saving equipment

- Energy & Utilities: Maintaining safety and compliance for boilers, pipelines, and compressors

Where We Calibrate Pressure Instruments

In-House Pressure Calibration Lab

Our ISO 17025-accredited calibration lab is equipped with high-precision tools and systems for detailed, repeatable measurements. We provide:

- Fast turnaround for standard and high-accuracy requirements

- NIST-traceable calibrations with comprehensive documentation

- Specialized capabilities for pressure gauges calibration services in aerospace, manufacturing, and energy sectors

On-Site Pressure Calibration Services

ICS offers on-site pressure calibration at your facility to reduce downtime and maintain operational continuity. Our technicians bring portable pressure gauge calibration equipment and expertise directly to your production floor.