Dayton’s Aerospace Defense Corridor Depends on Precision Calibration

Why Dayton’s Aerospace Defense Corridor Depends on Precision Calibration A Behind-the-Scenes Look at Instrument Calibration Solutions Dayton Lab

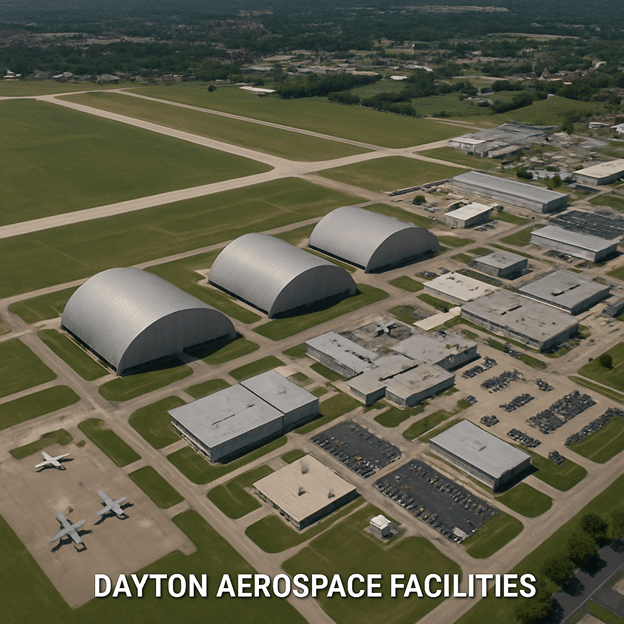

Dayton is a powerhouse in the aerospace defense industry. Known as the Aerospace Defense Corridor, it plays a vital role in national security. Precision calibration is the backbone of this industry, ensuring every instrument functions flawlessly.

Calibration labs in Dayton are at the forefront of technology. They provide essential services that maintain the accuracy and reliability of aerospace systems. These services are crucial for both military and commercial applications.

Electrical calibration is a key component of these services. It ensures that electronic systems operate correctly, preventing costly errors and enhancing safety. The importance of accuracy in aerospace cannot be overstated.

Dayton’s strategic location and resources make it an ideal hub for these services. The local economy thrives on the aerospace defense sector, driving innovation and growth.

Summary

Dayton’s Aerospace Defense Corridor relies on rigorous, state-of-the-art calibration—especially electrical—to keep mission-critical systems accurate, safe, and compliant. Leading local labs like Instrument Calibration Solutions deliver comprehensive, standards-driven services that underpin navigation, communication, and other high-stakes functions. Precision calibration reduces risk, boosts performance and readiness, and extends equipment life while meeting strict regulations. As systems grow more complex, Dayton is advancing with digital, automated innovations and industry–academia collaboration to sustain its leadership.

Dayton’s Aerospace Defense Corridor: A Hub of Innovation and Security

Dayton serves as a crucial hub for aerospace defense. The region’s strategic location supports various military and civilian functions. This has cemented its status as a pillar of national security.

The area is rich in resources and expertise, drawing top talent to its industries. Dayton’s firms collaborate closely with defense organizations to advance aerospace technologies. This synergy fuels innovation and economic growth.

Key Features of Dayton’s Aerospace Corridor:

- Advanced research facilities

- Access to skilled workforce

- Support from local government

Dayton’s aerospace defense activities are supported by robust infrastructure. The presence of major defense contractors fosters an environment of security and progress. Innovation in this corridor helps maintain the competitiveness of the U.S. aerospace industry.

The Critical Role of Precision Calibration in Aerospace Defense

Precision calibration is vital in the aerospace defense industry. Accurate measurements ensure that complex systems function flawlessly. Calibration maintains the integrity and safety of these high-stakes operations.

Without precise calibration, the risk of errors increases significantly. These errors can lead to system failures, affecting defense capabilities. Calibration is essential to keeping aerospace equipment reliable and effective.

Importance of Precision Calibration:

- Ensures accurate data

- Reduces operational risk

- Maintains compliance with standards

The aerospace sector relies on a variety of instruments and systems, each requiring precise calibration. Consistent calibration supports functions like navigation and communication. It helps prevent costly errors and enhances mission success.

In Dayton, labs use state-of-the-art technology to provide top-notch calibration services. These services meet rigorous industry standards and enhance system reliability. Precision calibration safeguards critical aerospace operations from potential pitfalls.

Inside Instrument Calibration Solutions: Dayton’s Leading Calibration Lab

At the heart of Dayton’s aerospace defense calibration is Instrument Calibration Solutions. This lab is equipped with cutting-edge technology. It ensures that every piece of equipment meets the highest industry standards.

The lab provides comprehensive calibration services for a range of instruments. From mechanical devices to complex electronics, precision is their hallmark. Calibration experts at the lab are highly skilled and dedicated to excellence.

Features of Instrument Calibration Solutions:

- Advanced technology and equipment

- Skilled and certified technicians

- Comprehensive range of services

Instrument Calibration Solutions plays a crucial role in the aerospace defense corridor. Its services are vital for maintaining equipment reliability and safety. By using state-of-the-art technology, the lab ensures accuracy in every calibration.

This commitment to precision supports both commercial and defense sectors. The impact of Instrument Calibration Solutions extends beyond Dayton, enhancing aerospace systems globally. The lab’s work underpins essential defense and aerospace operations.

Francisco Gonzalez (https://unsplash.com/@franciscoegonzalez)

Electrical Calibration: The Backbone of Modern Aerospace Systems

Electrical calibration is critical in aerospace defense. It ensures that all electronic systems operate accurately. Without it, errors could jeopardize safety and performance.

Calibration for electrical components is complex and precise. It involves testing and adjusting instruments to industry standards. By maintaining precision, electrical calibration supports crucial aerospace applications.

Key Elements of Electrical Calibration:

- Precision in electronic systems

- Regular testing and adjustments

- Adherence to industry standards

In Dayton, experts perform electrical calibration to the highest standards. By ensuring accuracy, they maintain the integrity of aerospace systems. This calibration supports functions such as communication and navigation.

Electrical calibration is foundational to successful aerospace operations. Without it, the reliability of systems cannot be guaranteed. Dayton’s services ensure that these essential systems function optimally.

by colsan ltda (https://unsplash.com/@plataformacolsan)

Ensuring Accuracy and Compliance: Standards, Regulations, and Best Practices

Accuracy and compliance are non-negotiable in aerospace defense. Calibration helps achieve these by aligning instruments with strict standards. This alignment prevents costly errors and enhances safety.

Key Elements in Calibration:

- Adherence to international standards

- Comprehensive documentation practices

- Continuous quality checks

Standards and regulations guide calibration processes in the industry. These rules ensure that aerospace systems meet rigorous benchmarks. Compliance with these standards is vital for mission readiness and performance.

Best practices in calibration include routine checks and training. Continuous development ensures that technicians maintain high skill levels. Labs in Dayton use advanced tools to meet evolving aerospace demands effectively.

The Impact of Calibration on Safety, Performance, and Mission Readiness

Calibration directly influences the safety and efficiency of aerospace systems. Properly calibrated instruments ensure that communication and navigation devices perform optimally. This precision is crucial for executing defense missions without errors.

Accurate calibration supports mission readiness by minimizing the risk of equipment failure. Well-calibrated instruments provide reliable data, essential for decision-making processes. This reliability reduces the chance of mission delays or cancellations.

Benefits of Precise Calibration:

- Improved safety measures

- Enhanced system performance

- Better decision-making processes

Safety and performance are not just about equipment reliability. Calibration also plays a role in extending equipment lifespan. This extension reduces the need for frequent replacements, aiding in cost management.

Challenges and Innovations in Aerospace Defense Calibration

The rapid advancement of aerospace technology presents ongoing calibration challenges. As systems become more complex, maintaining precision becomes increasingly demanding. Calibration labs must continuously adapt to these evolving technologies.

Innovations in calibration are crucial to meet these challenges head-on. Digital tools and automated systems are being integrated into calibration processes. This integration increases efficiency and accuracy, ensuring systems keep pace with technological advances.

Key Innovations:

- Digital calibration tools

- Automated precision systems

- Enhanced data analytics

These innovations help address the complexities of modern aerospace systems. By embracing cutting-edge solutions, calibration services remain at the forefront of technological progress. This progress supports the consistent reliability required in defense operations.

The Future of Calibration in Dayton’s Aerospace Defense Industry

Dayton’s role in aerospace defense calibration is set to expand with emerging technologies. New advancements in digital calibration are poised to enhance efficiency and precision further. These innovations are vital for keeping pace with the evolving demands of the industry.

Collaboration between local industry and academia will foster innovation. This partnership aims to address complex challenges and drive progress. As technology advances, Dayton is well-positioned to lead in calibration solutions for aerospace defense.

Conclusion: Why Precision Calibration Keeps Dayton at the Forefront

Precision calibration is vital for Dayton’s aerospace defense success. It underpins innovation, safety, and performance while supporting mission readiness. By investing in cutting-edge calibration solutions, Dayton remains a leader in the aerospace defense sector, contributing to both local and national security advancements.

Q&A

Question: Why is Dayton considered an ideal hub for aerospace defense calibration?

Short answer: Dayton combines strategic location, advanced research facilities, and a highly skilled workforce, all supported by local government and major defense contractors. Close collaboration between local firms and defense organizations fuels innovation, strengthens national security functions, and drives regional economic growth. This ecosystem creates the infrastructure and expertise needed to sustain state-of-the-art calibration services.

Question: What makes precision calibration indispensable in aerospace defense? Short answer: Precision calibration ensures accurate measurements across complex systems, which is critical to safety, reliability, and mission success. It reduces operational risk, prevents costly errors and failures, and maintains compliance with stringent industry standards. Consistent calibration underpins mission-critical functions like navigation and communication, keeping equipment effective and ready.

Question: Why is electrical calibration called the backbone of modern aerospace systems?

Short answer: Modern aerospace depends heavily on electronics, and electrical calibration keeps those systems operating accurately. It involves rigorous testing and adjustment to industry standards, ensuring communication, navigation, and other electronic subsystems perform as intended. By catching drift and inconsistencies early, electrical calibration prevents errors that could jeopardize safety and performance.

Question: What role does Instrument Calibration Solutions play in Dayton’s Aerospace Defense Corridor?

Short answer: Instrument Calibration Solutions is a leading local lab equipped with cutting-edge technology and staffed by skilled, certified technicians. It delivers comprehensive calibration services—from mechanical instruments to complex electronics—meeting the highest industry standards. Its precision work enhances reliability and safety for both defense and commercial sectors, with impact extending beyond Dayton.

Question: How does calibration influence safety, performance, and mission readiness—and what’s next for Dayton?

Short answer: Proper calibration delivers reliable data, minimizes equipment failures, and supports confident decision-making, boosting safety and overall system performance. It also extends equipment life and reduces costs by preventing premature replacements. Looking ahead, Dayton is advancing with digital tools, automation, and enhanced analytics—supported by industry–academia collaboration—to meet rising complexity and maintain leadership in aerospace defense calibration.