Compliance-Ready Calibration. Zero Guesswork.

Every industry operates under its own demanding set of regulations—and calibration is often at the core of maintaining compliance. Whether you’re governed by FAA and AS9100 requirements in aerospace, FDA 21 CFR Part 820 and ISO 13485 in medical devices, or IATF 16949 in automotive manufacturing, your instruments must perform within strict tolerances and be backed by traceable documentation.

Instrument Calibration Solutions (ICS) ensures your calibration program aligns with your specific industry’s standards, regulations, and quality management systems. Our ISO/IEC 17025–accredited laboratories and certified field technicians provide NIST-traceable calibration services, detailed data reports, and precise documentation that hold up under audit scrutiny. With ICS, you can expect a calibration process that’s accurate, compliant, and dependable—designed to keep your operations inspection-ready and production flowing.

How ICS Fits Your Operation

ICS designs calibration programs that integrate seamlessly into your operations. We deliver complete service coverage for a wide range of measurement disciplines—including dimensional, force, torque, pressure, electrical, and temperature—so your entire instrument inventory can be managed under one trusted partner. Each program is tailored to the standards and documentation your governing body requires, ensuring consistency across every audit and production phase.

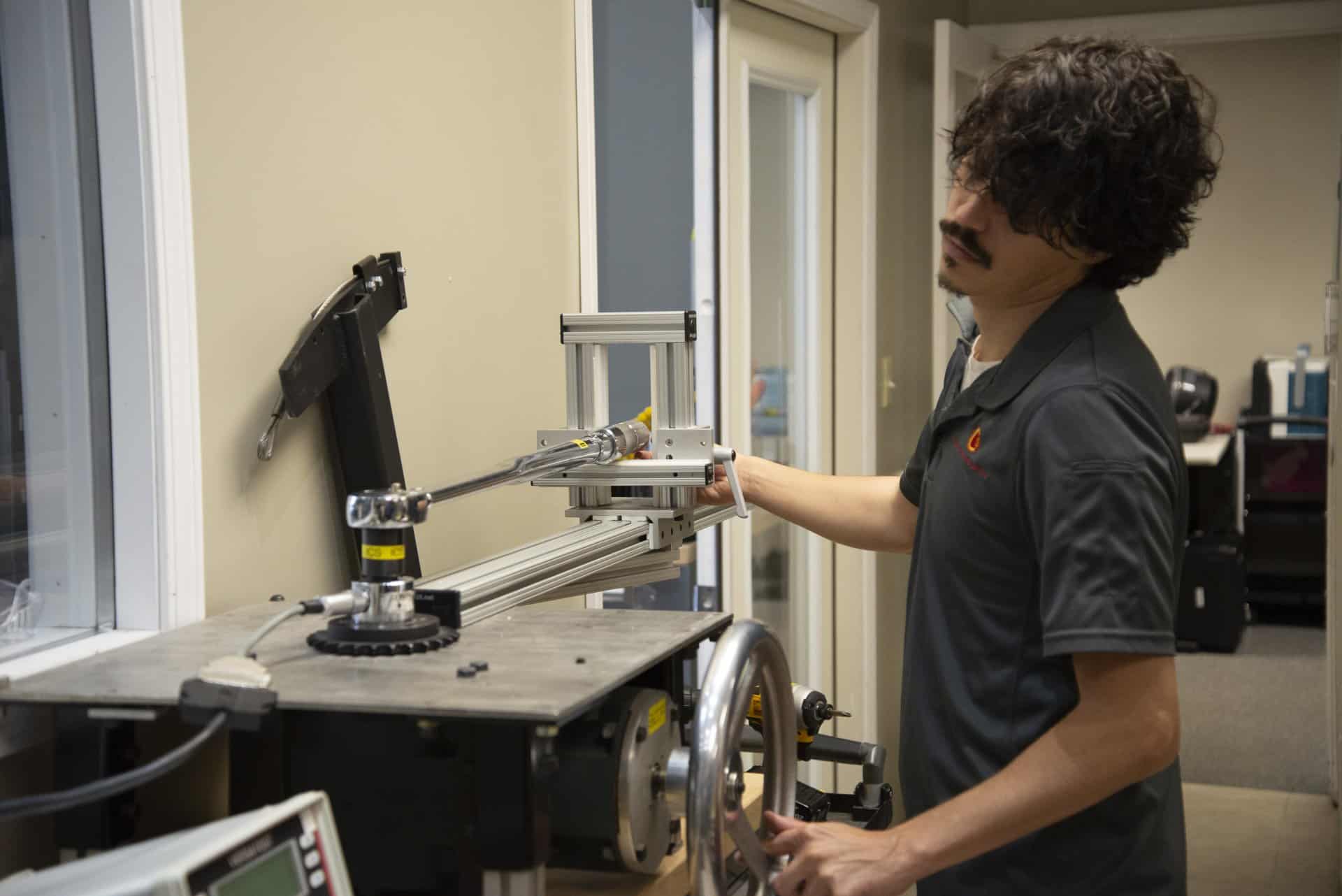

Our services are performed in our ISO/IEC 17025–accredited laboratories or directly at your facility through our on-site calibration teams. This flexibility allows you to maintain quality standards without disrupting workflow or production timelines. Whether you’re preparing for an audit, validating a new process line, or maintaining ongoing calibration intervals, ICS provides the expertise and reliability needed to keep your compliance intact.

Our calibration solutions serve quality and compliance managers, engineers, and procurement professionals who demand dependable results, clear documentation, and a streamlined process. ICS partners with your team to define calibration intervals, establish acceptance criteria, and ensure all records align with your QMS or production documentation system.

Trusted by Industry Leaders Across Sectors

ICS serves a wide range of industries where precision and compliance aren’t optional—they’re critical to success. In the aerospace sector, we help manufacturers and suppliers maintain alignment with FAA, AS9100, and NADCAP standards, providing calibration and documentation structured for airworthiness and special-process audits. Our services ensure that your measurement systems meet the performance and traceability demands required in aviation production and testing environments.

For medical device manufacturers, ICS delivers calibrations that fully support FDA 21 CFR Part 820 and ISO 13485 compliance. Our process includes controlled calibration intervals, as-found/as-left data reporting, and complete traceability to NIST standards—providing confidence that every instrument supports safe, reliable, and compliant product performance.

In the automotive industry, we support production facilities and test labs governed by IATF 16949 and OEM-specific requirements. ICS ensures calibration records and reports integrate smoothly into PPAP, CP, and MSA documentation workflows. The result is a cohesive, validated calibration program that strengthens quality control, reduces downtime, and meets every audit requirement.

Beyond these core sectors, ICS expertise also extends to pharmaceuticals, energy, and semiconductor manufacturing—industries that demand the same level of rigor and reliability in measurement and documentation.

Industry Precision. Proven Compliance.

ICS provides more than just calibration—we provide assurance. Every service we perform is backed by ISO/IEC 17025 accreditation and NIST traceability, giving you complete confidence in the integrity of your measurements. Our documentation is structured for both internal quality systems and external audits, so you’re never scrambling to prove compliance before an inspection.

We recognize that production schedules and quality requirements vary by facility, which is why our flexible calibration options—both in-lab and on-site—are designed to fit your operation. Our certified field teams bring the same level of precision and control to your location that we maintain in our laboratories.

With ICS, you gain a partner who helps define calibration intervals, acceptance criteria, and documentation formats that match your processes. By consolidating multiple calibration disciplines and repair services under one accountable source, ICS simplifies vendor management and keeps your equipment operating within specification year-round.