Helping a Manufacturer Navigate Audit Pressure with ISO/IEC 17025- Compliant Calibration and Digital Traceability

When audit readiness is critical, having immediate access to accurate, accredited calibration documentation can make the difference between passing and costly delays. Instrument Calibration Solutions (ICS) partnered with a manufacturer undergoing a third-party audit to ensure full compliance, traceability, and confidence under scrutiny.

The Challenge

The client was preparing for an external audit and faced growing concern around documentation, traceability, and proof of calibration. During the audit, inspectors requested immediate evidence that specific instruments were calibrated, compliant, and traceable to national standards.

Like many organizations, the client feared:

1

Scrambling to locate calibration certificates

2

Unclear documentation slowing down the audit process

3

Potential findings related to insufficient test points or standards interpretation

4

Uncertainty about whether their calibration approach would satisfy the auditor’s expectations

The Opportunity

The audit created an opportunity for ICS to demonstrate not just calibration services, but true compliance partnership.

The client needed:

- Rapid access to calibration records

- Clear alignment with recognized standards

- Expert support to address auditor questions in real time

- Confidence that their calibration program would stand up to scrutiny

The Solution

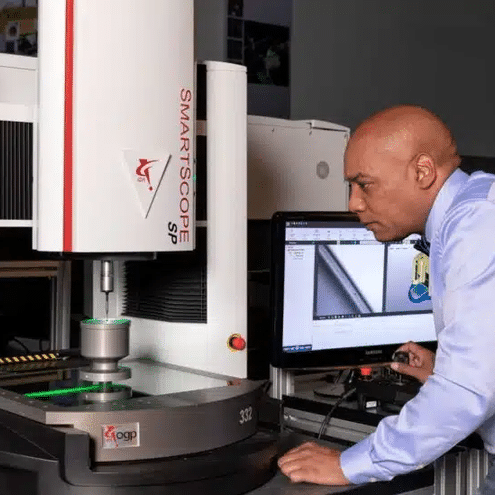

ICS supported the client using a combination of ISO/IEC 17025-accredited calibration, standards expertise, and ICS Live, its secure digital calibration management platform.

Key elements included:

1

Immediate digital access to calibration certificates through ICS Live, allowing the client to quickly retrieve documentation during the audit

2

Clear documentation of test points, tolerances, and referenced standards directly on calibration certificates

3

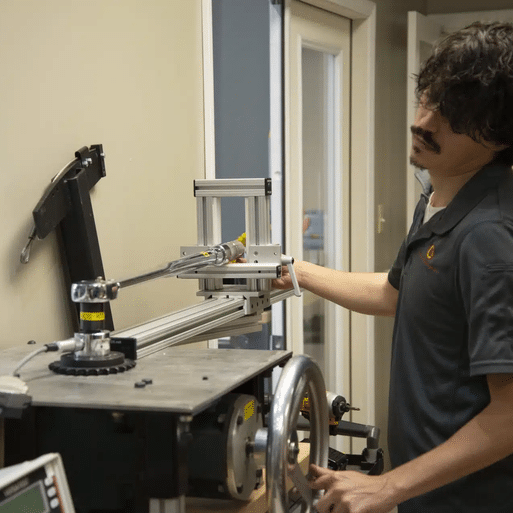

ICS experts referencing applicable standards (such as ASTM or B89) to explain and defend calibration methods used

4

Calibration performed in compliance with ISO/IEC 17025, with traceability to NIST

5

Consultative support when auditors questioned whether certain test points were sufficient for the equipment’s application

In cases where auditors requested changes after initial findings, ICS worked collaboratively with the client to adjust calibration approaches and retest equipment as needed to satisfy audit requirements.

Benefits

Eliminated audit stress through instant access to calibration records

2 Reduced audit interruptions and delays

Provided expert backing when auditors questioned calibration methods

Ensured calibration methods aligned with both customer and regulatory requirements

Reinforced trust in the client’s quality and compliance systems

Results

The client successfully addressed auditor questions and findings

Calibration documentation was verified quickly and confidently

Equipment compliance was clearly demonstrated and defended

The client gained greater confidence in future audits

ICS was positioned as a long-term compliance partner—not just a calibration provider