Calibration Partner in Western PA: ISO/IEC 17025

If you’re a Technical Director or Procurement Manager operating in the industrial heartland of Western Pennsylvania — think Pittsburgh, Coraopolis, Bridgeville, Monroeville, and Cranberry Township (all within roughly a 50-mile radius) — and you’re juggling dimensional gauges, electrical test instruments, thermodynamic sensors, and more, you’re in precisely the right place. You need a calibration partner with serious breadth: one vendor who can service multiple platforms, maintain full accreditation competence, and help you consolidate vendors instead of multiplying them.

Let’s cut to it: this is about simplifying your calibration logistics, reducing vendor count, and assuring your measurement uncertainty is accounted for — all while meeting compliance requirements. Here’s how to wisely evaluate a calibration partner’s scope of accreditation (that fancy-term document you rarely decode), how to ask the right questions, and why choosing a partner like Instrument Calibration Services (ICS) can pay dividends in the long run.

- Why ISO/IEC 17025 matters — and what “scope” really means

First things first: accreditation under ISO/IEC 17025 means a calibration laboratory has been assessed by a third-party body and found technically competent to perform calibrations for the parameters listed in its scope of accreditation. The standard itself “enables laboratories to demonstrate that they operate competently and generate valid results, thereby promoting confidence in their work.” ISO+1

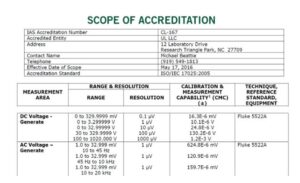

What many procurement folks miss is that not all calibrations are created equal. A lab might claim “ISO/IEC 17025 accredited” — but when you dig into the scope document, you may find it only covers a narrow band of services (say only temperature and humidity) rather than the full range your facility needs (dimensional, electrical, thermodynamic, etc.).

So for your industries (general manufacturing + life sciences) that have diverse instrument needs (gauges, calipers, multimeters, thermocouples, ovens, etc.), you need a partner whose scope covers all relevant domains — not just one.

- Key checklist questions for your calibration vendor

When you’re vetting prospective calibration vendors, here are pointed questions to ask:

- “Can you send your full scope of accreditation (not just a certificate) and clearly highlight where dimensional, electrical-DC/AC, and thermodynamic parameters are included?”

- “How do you report measurement uncertainty for each calibration parameter, and how does that uncertainty feed into our process controls?”

- “Do you support onsite calibration as well as in-lab service, especially for equipment that cannot easily be shipped?”

- “Can you handle multiple parameter types (dimensional, electrical, thermodynamic) under a single vendor contract — or will we still end up with separate vendors?”

- “What is your turnaround time? What about rush service?”

- “How do you help us schedule calibrations, track due dates, and reduce administrative overhead (i.e., vendor consolidation)?”

These questions align with known best practices for calibration service providers. Calibration Lab+1

Make no mistake: your risk isn’t just from instrument drift — it’s from calibration gaps. If you fragment your vendor list across too many narrow-scope labs, you increase management overhead, risk of missed calibrations, inconsistent uncertainty reporting, and ultimately non-conformance in audit-ready industries (especially in life sciences).

- Why vendor consolidation matters — especially in Western PA

Picture this: you have one logbook for dimensional calibrations handled by vendor A, another logbook for electrical calibrations handled by vendor B, and yet another for thermodynamic calibrations handled by vendor C. Multiply that across your plant network in Greater Pittsburgh (Pittsburgh, Coraopolis, Bridgeville, Monroeville, Cranberry Township) and you’ve got process complexity out the wazoo.

Now imagine consolidating everything under one vendor who:

- Maintains a broad scope of services, including dimensional, electrical, thermodynamic.

- Tracks instrument status for all types across your sites.

- Provides one vendor contract, one point of contact, one invoice.

- Minimizes vendor-management overhead and simplifies scheduling.

That’s the operational sweet spot — fewer vendors, fewer spreadsheets, less risk of something slipping through the cracks. And yes, that also means lower admin cost, stronger audit readiness, and greater peace of mind for you as the Technical Director or Procurement Manager.

- Why ICS is a strong fit for your needs

Let’s talk about why ICS is worth serious consideration. At a glance:

- They’re ISO/IEC 17025 accredited and you can verify their scope via their website. Instrument Calibration Solutions

- They offer calibration for temperature & humidity instruments in‐lab and on-site, which speaks to their service flexibility. Instrument Calibration Solutions

- Their industries served list includes manufacturing, life sciences (pharma/biotech), food & beverage, aerospace, etc., so they understand diverse instrument ecosystems. Instrument Calibration Solutions

- From an operational standpoint, choosing ICS gives you a single partner who can address multiple calibration parameters — thereby avoiding vendor proliferation.

In short: ICS delivers the “one-stop shop” value proposition that modern operations crave — especially when your plant is based around Pittsburgh and surrounding suburbs.

- How to evaluate measurement uncertainty and scope gaps

Speaking of measurement uncertainty: you’ll want to ensure that the lab’s certificates not only list the calibrated parameter but also publish measurement uncertainty. Why? Because when you’re comparing two alternative labs, a lower stated uncertainty (if properly verified) means tighter confidence in your measurement results, which translates to better process control, fewer rejects, and improved yield.

Also, scrutinize the scope for terms like “dimensional – calipers, micrometers, height gauges,” “electrical – voltmeters, multimeters,” “thermodynamic – temperature controllers, ovens” etc. If your vendor’s scope doesn’t list those categories explicitly, you’re accepting blind spots.

To make it concrete, here’s a hypothetical internal review snippet to capture feedback from your procurement review:

“We selected ICS because their in-house capabilities allowed us to reduce our vendor list by 50 %. They support dimensional, electrical and thermodynamic calibrations within one contract, their accreditation scope is publicly available, and our device scheduling is down from three systems to one.”

(Feel free to use a version of this quote in your internal memo.)

- Final recommendation & next steps

To wrap it up: As you fine-tune your calibration program across manufacturing or life-science operations in Western Pennsylvania, you must move beyond “is my vendor ISO/IEC 17025?” to “does their scope cover everything we need?” Vendor consolidation is not just trendy — it’s smart logistics and risk mitigation. Choosing a partner with broad scope and single-point management (like ICS) not only reduces overhead but strengthens your compliance posture and operational efficiency.

Next steps for you (the procurement/technical lead):

- Ask ICS (and your other contenders) for a full scope of accreditation.

- Map your instrument inventory (dimensional gauges, electrical test sets, thermocouples, ovens, etc.) to the scope PDF and highlight any gaps.

- Set a vendor-consolidation target (for example: reduce calibration vendors from 5 to 1 within 12 months).

- Build a simple instrument tracking spreadsheet aligned with the new vendor’s notification system and set calibration intervals based on risk and use (annual, semi‐annual, etc.).

- Communicate internally: remind QA/operations that calibration is not just “nice to have” — it’s the measurement assurance underlying product quality, regulatory compliance and audit readiness.

By focusing on scope, measurement uncertainty, and vendor consolidation, you’ll position your operation not just to stay compliant — but to move ahead, efficiently, confidently and with fewer headaches. And frankly, as the metrics-driven person you are, you’ll sleep a little better at night knowing the calibration roster is streamlined, the risk exposure reduced, and the vendor contract simplified. Let’s get you from scattered vendor chaos to lean, well-orchestrated calibration operations.