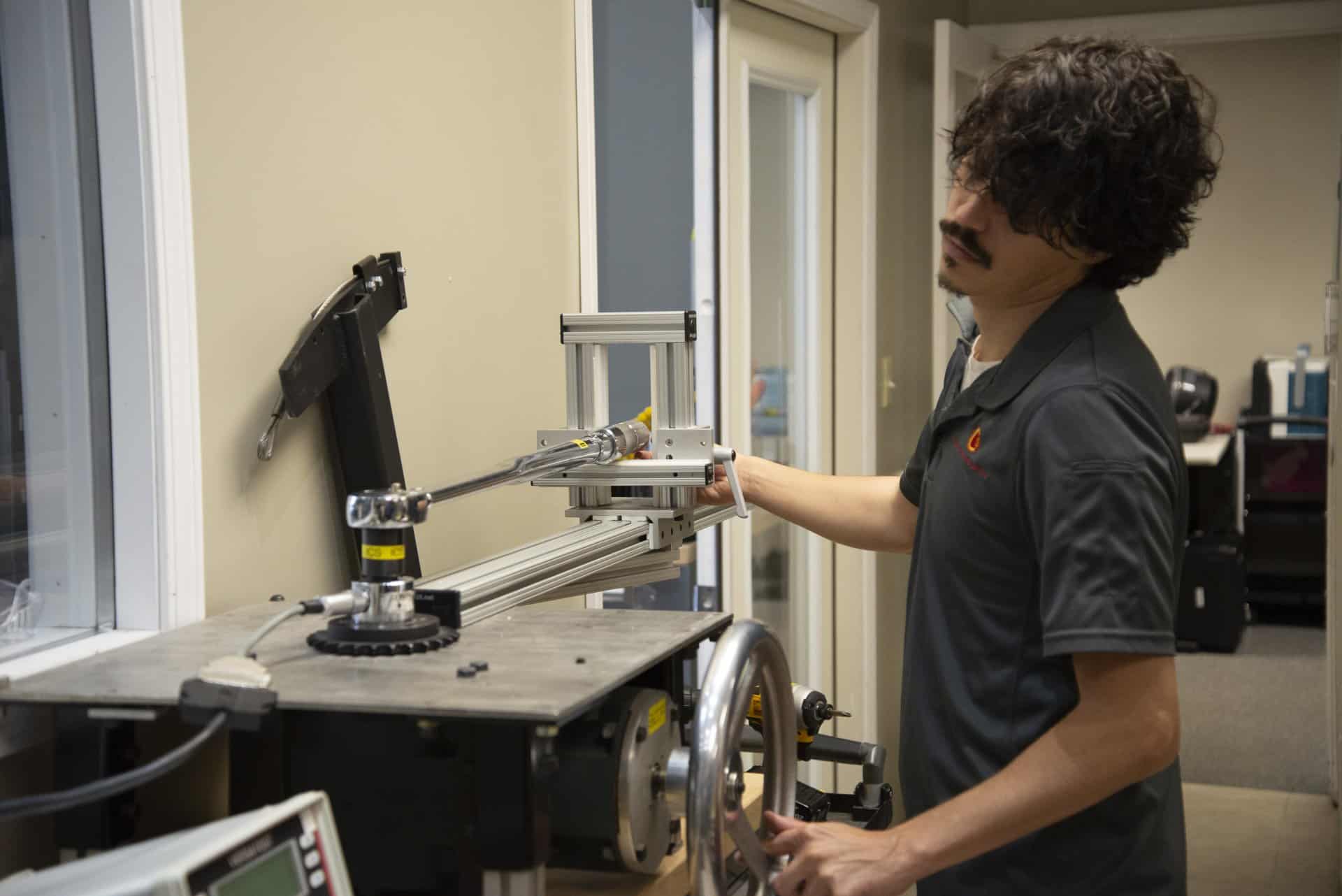

Torque Calibration Services

Precision. Compliance. Confidence.

At Instrument Calibration Solutions (ICS), our ISO 17025-accredited torque calibration services ensure your tools deliver accurate, repeatable force—every time. From click wrenches to high-capacity hydraulic tools, we provide NIST-traceable calibrations that meet the highest industry standards, whether performed in our lab or at your facility.

ICS partners with quality professionals, maintenance managers, and procurement teams across aerospace, automotive, medical, energy, and other precision-driven sectors. We don't just calibrate tools—we safeguard your operations, protect your compliance, and power your performance.

What is Torque Calibration?

Torque Calibration verifies and adjusts torque tools—like wrenches, screwdrivers, and multipliers—to ensure they apply the correct amount of force. This prevents over-tightening or under-tightening, which can damage parts, cause equipment failures, or create safety risks.

Over time, torque tools drift out of spec. Environmental conditions, mechanical wear, and frequent use all take a toll. Regular calibration ensures your tools meet performance and safety expectations.

Why It Matters:

- Avoid Failures: Prevent component damage and product malfunctions

- Ensure Compliance: Meet ISO, NIST, and industry standards

- Promote Safety: Critical in aerospace, automotive, and medical applications

- Protect Equipment: Extend the life of your torque tools

How It Works

Every torque calibration follows a proven process:

- Initial Inspection: Mechanical and visual checks

- Torque Testing: Across operational ranges

- Adjustments: Precision corrections to restore tool accuracy

- Final Verification: Ensure repeatability and performance

- Documentation: ISO/NIST-certified certificate with uncertainty data

Whether it's an in-lab calibration or an on-site service, your tools return to service accurate, compliant, and fully traceable.

Where We Do It

- In-Lab Calibration: Performed at our ISO 17025-accredited facility with top-tier precision and documentation

- On-Site Calibration: Nationwide field service for tools that can’t leave the facility or when minimizing downtime is critical

- Preventative Maintenance Programs: Scheduled services that help avoid disruptions, ensure compliance, and prolong tool life

Who We Serve

ICS supports a wide range of industries where torque precision is non-negotiable:

- Aerospace & Defense

- Automotive & Transportation

- Medical Devices & Healthcare

- Industrial & Contract Manufacturing

- Oil & Gas, Utilities & Construction

- Research & Development

- Energy & Power Generation

From QA managers and maintenance teams to calibration coordinators and safety officers, ICS provides scalable torque calibration solutions tailored to your role, facility, and compliance requirements.

Why ICS?

- ISO 17025 Accreditation

- NIST-Traceable Results

- Fast Turnaround Times

- In-Lab or Regional On-Site Service

- Reliable Reports for Audits & Compliance

- Decades of Technical Experience

With ICS, you gain a calibration partner who understands the stakes—and delivers with precision and purpose.